Solenoids Pumps Mechanism Applications Selection Factors Option Board

Selection Factors for Solenoid Pumps

Bear these factors in mind while selectiong solenoid pumps , or fill out Application Condition & Requirement Form (Optiona Board)

- Output Requirements:

- Fluid Type: Gas / Liquid, and its temperature, viscosity, corrosiveness, etc.

- Pressure that pump can overcome or generate.

- Suction Height: with empty inlet cube, the height between liquid surface and pump.

- Suction Length: with empty inlet cube, the tube length between liquid surface and pump.(Suction Height + L2)

- Suction Time: with empty inlet cube, the time liquid was pumped from source surface to pump outlet.

- Operation cycle: we define this as once “operational on time + following off time” of solenoid.

- Duty cycle: = On time /(On time+Off time)〕X100%

- Maximum on time.

(Duty cycle, Maximum on time, and power of solenoid decide temperature rise. While ambient temperature and temperature rise are vital factors of insulation class concerns. Ref.: Insulation Class = ℃: A=105, E=120, B=130, F=155, H=180, N=200, C=220+)

- Input Conditions

- Power Supply Type: different current wave shapes produce different solenoid motions. Supply may be: AC/DC (constant voltage / Current Supply, battery, dry cell, DC generator, capacitor), commutate and filer methods.

- Rated Voltage and operation voltage range. Maximum current capacity of the supply.

(Current or power is in proportion to force output within limited range. Force won’t increase any more with current / power increase when solenoid gained magnetic saturation.

In the mean time, temperature rise increases in proportion to current / power.)

- Environment Factor & Life:

These are critical for material and finish consideration.

Environment factors include: temperature; humidity; magnetic or electric field; gas, liquid, dust pollutants or corrosives; impact or vibration, etc.

- Connection methods of Assembling, Power supply and load; and dimensions.

- Assembly methods: a). external clamp bracket b). 187 quick connect terminals. Refer product.

- Power supply connection method: 187 quick connect terminals

- Load connection method: refer individual product or customer requirement.

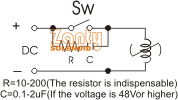

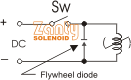

- Protection of Contacts in Driving Circuit.

The control contacts for use with the DC Solenoid may spartk, wear and cause noise interference. Provide a proper protection as the case maybe. Resistor & Capacitor Method Diode Insertion Method